Products

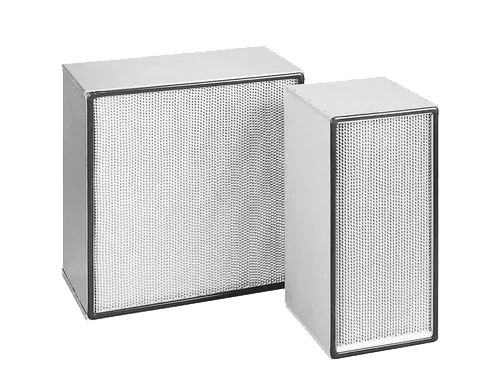

High-Flow, Low-Pressure-Drop HEPA Filters

Breathe easy with our innovative air filters

iTech’s high-flow, low-pressure-drop HEPA filters are highly efficient in optimizing airflow and reducing pressure drop. These filters maintain high efficiency with advanced media and design, and reduce energy costs significantly.

Paving the way for cleaner air: Purify your lives with iTech’s High-Flow, Low-Pressure-Drop HEPA Filters

Our high-flow, low-pressure-drop HEPA filters optimize airflow and decrease energy costs in vital applications. These filters are innovatively designed so that pressure drop is minimized and airflow is optimized. They have multiple mini-pleat media packs that can provide maximum filtration efficiency and high dust-holding capacity. Owing to their lower pressure drop as compared to other filters, they consume less energy, which makes them ideal for applications that require high air quality and efficiency.

Technical Features

EN1822 : H13 H14

Filter Depth: 292 mm

Media Type: Fiberglass

Frame Material:

- Galvanized Steel

- Stainless Steel

- Aluminium

Gasket Material: Neoprene

Max Operating Temperature: 70 °C

Activated Carbon Filters

How does it work?

These filters have multiple mini-pleat media packs, which are an advanced design feature. Mini-pleats are the small folds of the filter media that are compactly packed. Unlike conventional pleated filters that have larger pleats, mini-pleat filters have more pleats per inch, which provides a much more compact arrangement. Using multiple mini-pleat media packs maximizes the effective media area available for filtration, which decreases the airflow resistance and ensures that the filter can trap a huge number of particles without getting clogged rapidly. Therefore, using this feature results in maximum filtration efficiency, high airflow capacity, low resistance, high dust-holding capacity, and a long service life.

Owing to the larger surface area resulting from the mini-pleat design, more particles are captured, and the filter can manage larger air volumes without a huge increase in pressure drop. This feature is advantageous in case of HVAC systems, where a huge pressure drop can cause a greater consumption of energy and decrease in the efficiency of the system.

The particles passing through the filter are eliminated using the mechanisms of interception, impaction, and diffusion.

- Interception – The particle follows a streamlined path and encounters a fiber or obstacle. The particle then gets attached to the fiber/obstacle and is unable to move further.

- Impaction – In inertial impaction, the web of fibers increases the inertia of the particles to a point where they are forced out of the air stream. The particles subsequently get trapped by the fibers and are not able to move any further.

- Diffusion – A particle travelling in a random motion undergoes collision with a fiber and is trapped by the fiber. This filtration technique is used to capture smaller particles.

Activated Carbon Filters

Applications

These filters are suitable for use in environments that require superior air quality as well as energy efficiency. The applications of these low-pressure-drop HEPA filters are given below.

- Semiconductor and electronics manufacturing: Semiconductor wafers and electronic components are manufactured in cleanrooms, which require extremely clean environments so that the manufactured products do not have any defects. Also, the HVAC systems used in the cleanrooms require a low pressure drop. Hence, these low-pressure-drop HEPA filters are used in the HVAC systems of cleanrooms to provide a low pressure drop as well as extremely pure air.

- Pharmaceutical processing: The environment in the pharmaceutical industry needs to be sterile and free from contaminants to ensure the quality of the product. Hence, low-pressure-drop HEPA filters are used in the HVAC systems of cleanrooms where the manufacturing of pharmaceuticals takes place. These filters eliminate harmful bacteria and viruses from these cleanrooms while providing a low pressure drop to the HVAC systems.

- Photo-film manufacturing/processing: In the manufacture and processing of photo films, the quality of the film needs to be maintained, thereby needing an ultra-clean environment. These photo films are manufactured and processed in cleanrooms that use HVAC systems. Our low-pressure-drop HEPA filters are utilized in these HVAC systems to capture dust and other contaminants.

- Hospitals, laboratories, and optical facilities: The HVAC systems in hospitals, laboratories, and optical facilities use our low-pressure-drop HEPA filters to maintain a sterile and clean atmosphere as well as to reduce energy consumption.

- Food processing: The environment in the food processing industry needs to be clean and free of contaminants in order to ensure that the manufactured food products are safe and of good quality. Hence, the HVAC systems in food processing plants use low-pressure-drop HEPA filters, which eliminate airborne contaminants.